Although now non-existent, cigar manufacturing and distribution stands out as one of the most storied among the many industries that once prospered in historic Lebanon County.

Cigar manufacturing was once an important component of the local economy and society. Many local cigar manufacturers started out by rolling cigars in their own homes, as tooling and equipment used in the cigar business was relatively inexpensive.

From the late 1800s to the mid-1900s, there were more than 30 cigar manufacturers that operated in Lebanon County. These manufacturers, in turn, led to ancillary businesses, such as cigar band and box manufacturers, as well as cigar and tobacco stores.

In 1928, there were 102 mercantile business licenses issued in Lebanon County to distribute and sell cigars. Local cigar brands included Abram Clark, Conrad Weiser, El Witto, Flor de Morrow, General George, Havanna Favorites, John Hay, and Mineota.

From 1916 through 1933, Lebanon County ranked 12th in Pennsylvania in cigar production. In 1927, the tobacco industry in Lebanon County employed 560 people and produced goods worth $1,230,600 ($19.2 million in 2021 dollars).

Invention of the cigar and its worldwide distribution

The first known use of tobacco, rolled into the form of a rudimentary cigar, occurred with the Central American Mayans around the 10th century. The Mayan word “sicar” means to smoke rolled tobacco. “Sicar” is almost certainly the source for the Spanish word “cigarro” and the English word “cigar.”

Mayan trade and migration into North and South America and the Caribbean Islands likely introduced the cigar to the indigenous peoples in these regions.

In 1492, when Christopher Columbus reached the Caribbean Islands, the indigenous people were smoking dried tobacco leaves wrapped in palm or plantain leaves. At that time, tobacco was unknown to Europeans. Columbus and other Age of Discovery explorers took tobacco back to Europe, and cigar-smoking became popular in a fairly short period of time.

The Spanish Empire built cigar factories in Cuba and limited their export to maintain high market prices. Europeans refined the cigar by tightly wrapping it in tobacco leaves instead of other plants.

In 1762-63, the availability of Cuban cigars expanded around the world as England temporarily occupied Havana, Cuba, during the Seven Years’ War, and distributed cigars in large numbers. As the availability of cigars increased, so did their worldwide popularity.

As Cuba fought for its independence in the Ten Years’ War (1868-1878), the instability caused by the rebellion forced many cigar manufacturers to relocate. Many large Cuban cigar operations were moved throughout the Caribbean, Central and South America, and to areas in the U.S., including Key West and Ybor City, Tampa, Florida’s northeast neighborhood, which rolled hundreds of millions of cigars annually from the 1880s to the 1930s.

By 1870, American cigar manufacturers were producing more cigars than Cuba, as there were nearly 1,500 cigar factories in the U.S. By 1890, the number of cigar factories in the U.S. grew to an estimated 3,500.

During the late 1800s and into the early 1900s, Pennsylvania’s cigar industry boomed. Philadelphia became one of the leading centers in the nation, and the small community of Red Lion in York County was manufacturing roughly 10% of all cigars produced in the country.

The peak of the cigar boom occurred in 1920, as an estimated eight billion cigars were made worldwide.

Cigar manufacturing in Lebanon County

In the 1920s, a good local cigar maker could roll 400 to 500 cigars a day and earn around $2 per 10-hour workday. Female tobacco strippers (the separating of tobacco leaves from their stalks) were paid about 15 cents per day, and female cigar box assemblers were paid around $1 per 10-hour workday.

Read More: Matchbook mix-up: a Lebanon genius is finally getting credit for his invention

Cigar flavors were produced by mixing tobacco grown in various types of soil from different areas. To this end, Lebanon County cigar manufacturers used locally grown tobacco as well as tobacco purchased from Connecticut, Maryland, New York, Ohio, Virginia, and Cuba. Cigar manufacturers kept their cigar-making formulas secret, as they were the key to their uniqueness, and thus to business success.

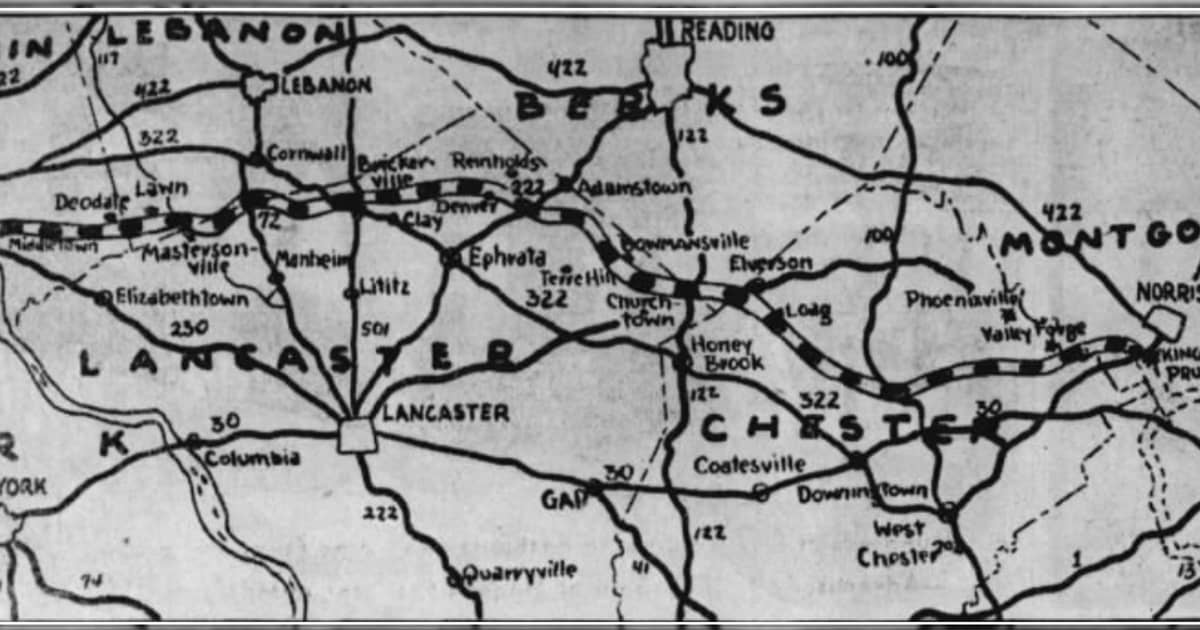

The eastern part of Lebanon County had the largest concentration of cigar manufacturers. The following are some of the cigar industry companies that once existed in Lebanon County, listed by municipality:

City of Lebanon

H.C. Gallagher Cigar Store and Factory was founded in the 1880s at 17 N. 8th St. Some of the cigar brands that Gallagher distributed included Henry Clay, Lady Ann, La Prima Ross, and La Juntida. The company went out of business after Gallagher’s death in 1912.

D.B. Long & Co. cigar manufacturer started in the 1880s at 6th and Lehman streets, and it later moved to 6th and Cumberland streets.

The Swope Brothers manufactured cigars from about 1880 to around 1910 at Ninth and Scull streets.

John H. Witter Cigars started in 1923 at 10th and Mifflin streets, and it reportedly had the capacity to employ about 150 people.

Fredericksburg

Zerbe Cigars started in the 1890s and was sold in 1924 to Daniel C. Mohn, who operated it under his name until its closing in the mid-1930s.

M.C. Bressler Cigar Manufacturer was founded by Miles Bressler, who purchased the former Schuylkill Seminary building in 1907 and repurposed it into a large cigar factory that remained in business until the 1930s. The Bressler Cigar company was locally known as the “Factory on the Hill.”

Myerstown Borough

Witter Brothers Cigar Manufacturers was located on West Carpenter Avenue and expanded to Reamstown, where they employed more than 50 workers.

Valentine & Son Cigar Manufacturing Co. was founded in 1921 from the mergers of A.S. Valentine & Son (Womelsdorf), Ibach & Rader Cigar Factory (Newmanstown), and Bennett & Sloan Co. (New York). It was located at 23 W. Washington Ave.

The cigar box manufacturer, Daniel Holtzman, was located on South Railroad Street.

Newmanstown

W.W. Stewart & Sons was founded in 1882 and moved to Reading in 1898.

Ibach & Rader Cigar Factory made several brands, including Abram Clark, Flor de Morrow, and Havanna Favorites.

J.H. Witter Cigar Co. once made a “monster” four-foot-long cigar in 1926 to advertise at a fair in Trenton, New Jersey.

Other cigar makers included Zimmerman and Grimes, and F.A. Noil.

Richland Borough

Samuel Klopp and Hertzler & Kline founded cigar and tobacco companies around 1871.

By the early 1900s, Richland was a significant cigar-making center as manufacturers included Lloyd H. Layser, M.J. Klopp & Bros., Seth Layser, John S. Steinmetz, and Klopp & Keggereis.

In 1911, the cigar box manufacturer M.H. Wiest & Son installed a 40-horsepower generator to support his machinery in keeping up with busy orders.

Schaefferstown

Notable manufacturers included A.B. Horst’s Cigar Factory, Olympus Cigar Co., Grim and Rush, later known as Rush, that employed over 150 people during its peak production, T.T. Zerbe & Bros., and Calvin Mentzer and Mock Bros.

In 1922, the veteran tobacconist Samuel Houser opened up a cigar box manufacturing business.

When there’s a boom, there’s often a bust

Several factors contributed to the drastic decline in the cigar industry.

Starting in 1929, the Great Depression caused American cigar manufacturers to scramble to make a more affordable product. The nickel cigar was popularized and soon became the industry standard. However, low profits and declining demand drove many manufacturers out of business.

In the 1930s, cigarettes became stylish, weakening the market for cigars. Starting in the 1940s, smoking cigars was forbidden on most planes, buses, and trains, further weakening the market.

In 1964, the U.S. Surgeon General released the “Report on Smoking and Health,” which required warning labels on tobacco products and banned many forms of advertising. This contributed to health concerns and boosted a concentration on physical fitness over the next few decades, contributing further to declining cigar usage and sales.

Read More: Clarence Schock Memorial Park designated as tobacco- and vape-free location

Read More: Lebanon VA among sites implementing nationwide smoking ban Tuesday

In addition, women and the under-40 generation, both of which make up a huge part of the consumer market, are buying few cigars today.

All of these factors have driven the purchasing of cigars downward in today’s marketplace.

The legacy of Lebanon County’s cigar industry

By the 1950s, Lebanon County’s once-booming cigar industry was gone. During its heyday, it provided hundreds of jobs and created wealth for many families and local communities.

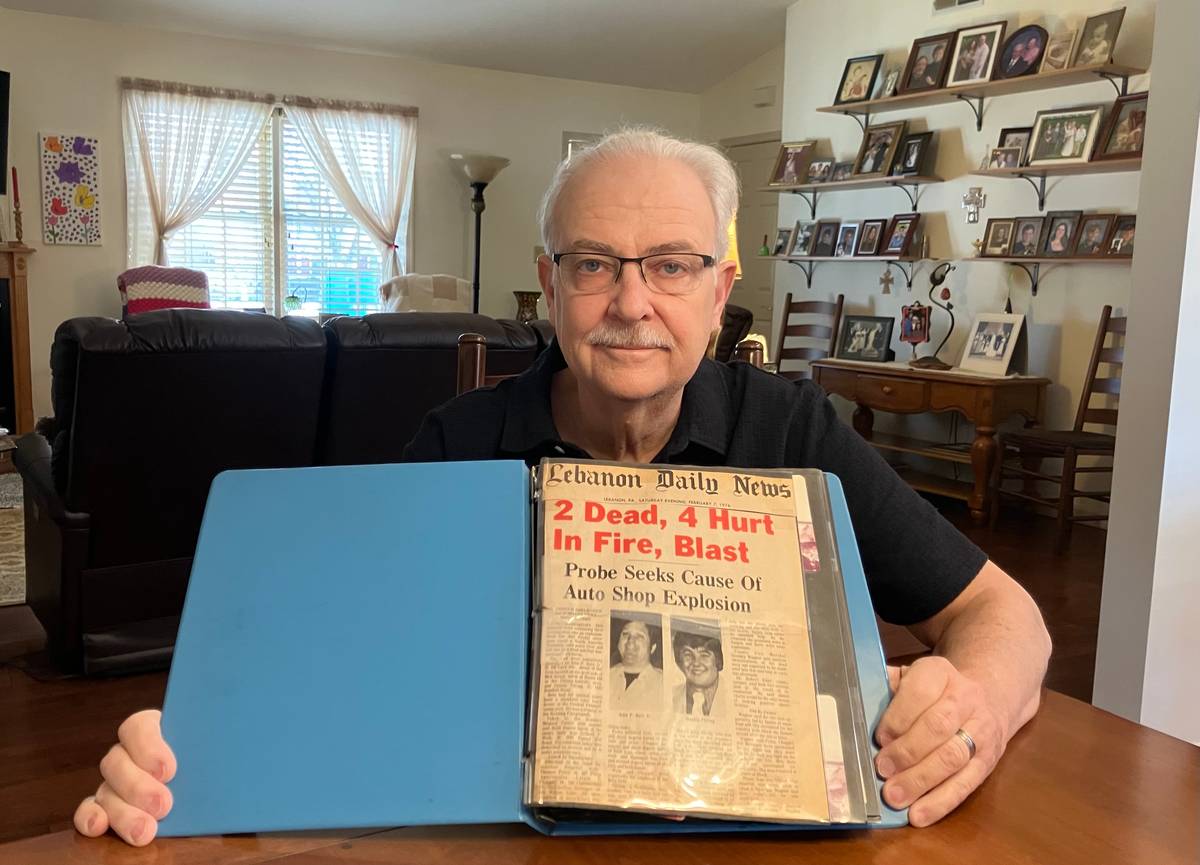

Remnants of the historic industry survive in artifacts such as pictures, etchings, cigar boxes, company paperwork, advertisements, and newspaper and magazine articles.

Starting in 2006, the community of Richland recognizes their cigar heritage by dropping a 10-foot long by 12-inch diameter cigar on New Year’s Eve to ring in the new year.

It is not likely that the cigar manufacturing industry will ever return to Lebanon County.

Original Newmanstown cigar now distributed from Intercourse

The John Hay cigar brand was created in 1882 and originally made at W.W. Stewart & Sons Cigars in Newmanstown. The company moved to Reading in 1898 and remained in business until the early 1950s.

In the early 1990s, Craig Stewart, great-grandson of W.W. Stewart, reintroduced the brand (although the original 1882 recipe is not known) under the name of John Hay Cigars in Reading. At this time, John Hay cigars were being handmade in McSherrystown, using Connecticut and Pennsylvania broadleaf tobacco, which is primarily grown in Lancaster, Chester, and York counties.

In 2004, David and Lauren Patrick assumed ownership and are currently operating the business in Intercourse. John Hay cigars are being handmade in New Jersey and in the Dominican Republic, and are rolled from Pennsylvania broadleaf tobacco and the Dominican Republic and Nicaraguan plants.

The original Lebanon County John Hay cigar brand lives on by its name and the design on their cigar bands and boxes.

Does the cigar industry have a future?

According to Alex Unkow, manager at the D&S Cigar Lounge in Lancaster, “the COVID-19 pandemic has actually increased demand for premium handmade cigars.” He also pointed out that the FDA is considering easing regulations on premium handmade cigars. As a result, the small niche cigar industry appears to have a future market.

However, the mass-manufactured cigar industry, which consists of flavored and infused brands, continues to decline, and its future does not look promising.

Acknowledgements

Pat Rhen, a Lebanon County history buff, provided information, and David and Lauren Patrick, owners of the John Hay Cigar Co., provided information, pictures, and a cigar box to support this article.

Questions about this story? Suggestions for a future LebTown article? Reach our newsroom using this contact form and we’ll do our best to get back to you.

Keep local news strong.

Cancel anytime.

Monthly Subscription

🌟 Annual Subscription

- Still no paywall!

- Fewer ads

- Exclusive events and emails

- All monthly benefits

- Most popular option

- Make a bigger impact

Already a member? Log in here to hide these messages

Trustworthy local news is built on facts. As Lebanon County’s independent news source, LebTown is committed to providing timely, accurate, fact-based coverage that matters to you. Support our mission with a monthly or annual membership, or make a one-time contribution. Cancel anytime.